Get A Quote

To request a quote, please fill out the form below. A representative will respond to you as quickly as possible. Thank you.

NewBlog

- Home

- >

- NewBlog

There are several different rock crusher options, and each is used for slightly different purposes. When choosing a rock crusher for your operations, it’s important to first identify the stage of crushing you’re using the machine for. This will determine the appropriate solution for your needs.

Impact, Cone, and Jaw Crushers from Power Screening Equipment

Rock Crushing Stages

There are three different stages of concrete crushing:

- Primary – This stage involves crushing coarse materials in order to allow them to be transported on a conveyer belt. These machines need to be able to handle a large capacity and accept the raw materials without suffering a blockage.

- Secondary – In this stage, the coarse materials produced during primary crushing are broken down even more in preparation for final crushing. The purpose of secondary crushing is to achieve the greatest possible reduction in particle size for the lowest possible cost.

- Tertiary – This stage further refines particles to make them as fine as possible. The quality and quantity of fine products must be considered when determining the right concrete crusher for this phase of the process.

Screening equipment performs essential functions for a variety of aggregate processing applications. In order to ensure this important task is completed properly, you’ll need to choose the right screening equipment for the specific sorting task associated with your application.

Screening plants are used to size and separate rock materials after crushing. During the screening process, these materials are separated into grades based on their particle size. In some instances, screening plants are used to separate materials immediately following the primary crushing phase, while other applications use screening equipment later in the process, right before materials are stockpiled for transport.

The following factors will determine which screening plant is right for your specific application.

Why Are You Screening Materials?

One of the most important factors impacting the right screening equipment to choose is the reason why you are screening these materials. There are several reasons this task is performed:

- To split a feed stream into different processing lines

- To compile a product containing specific particle characteristics

- To remove a specific product in preparation for a future crushing step

- To remove fine particles from larger ones

Choosing the right screening plant for your specific purpose will significantly impact both the quality of your finished product and the capacity of your processing system.

Screen Plant Operating Characteristics

Make sure you consider the following operating characteristics when choosing screening equipment:

- Feed rate – Consistent feed is crucial to ensuring the process is completed properly. Otherwise, you may end up with too much oversize material when the screen load is low and too many fine particles when the screen load is high.

- Bed depth – The depth of material on the screen impacts how well it will separate the material to remove your desired particle size.

- Screen Openings – The design of the screen openings will impact the efficiency and capacity of the equipment, as well as the quality of product produced. As the space between holes decreases, capacity often increases.

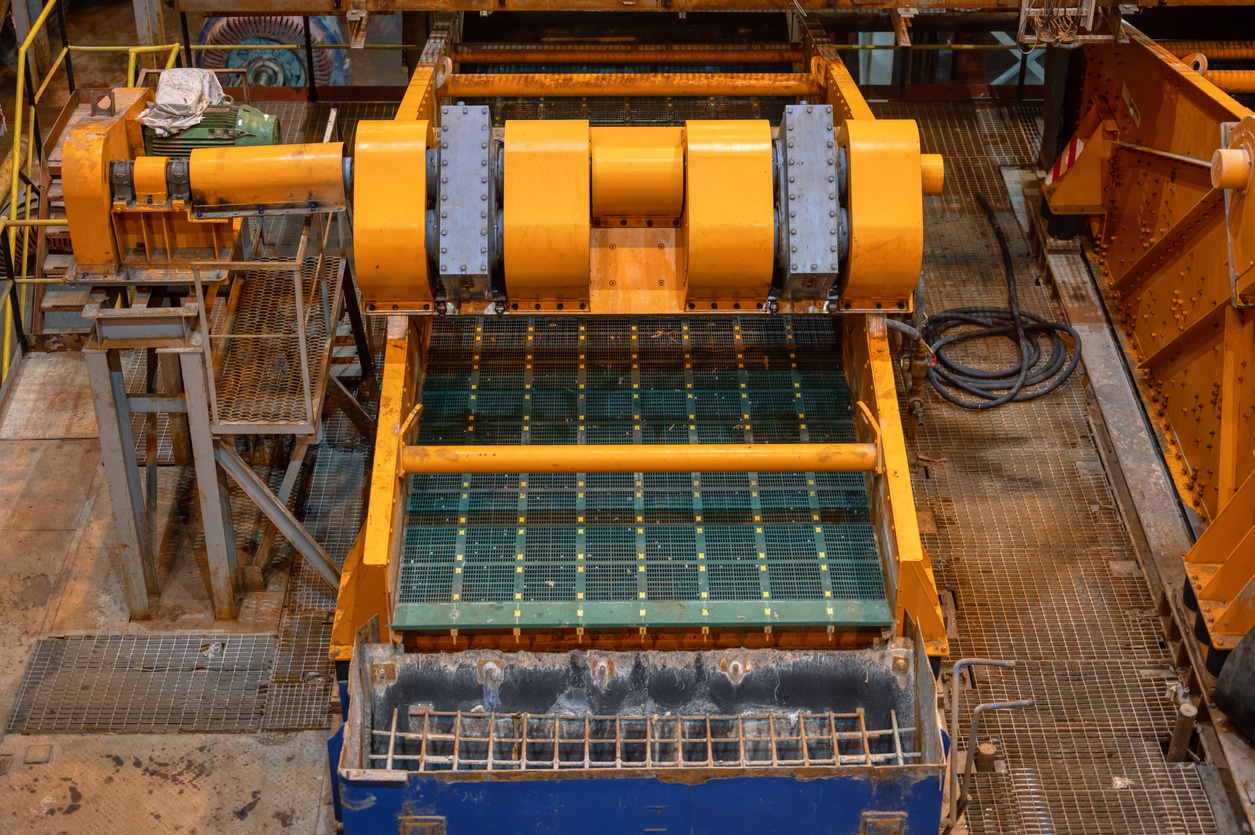

Types of Screening Equipment

There are two types of screening equipment:

- Horizontal screens

- Incline screens

Each option is ideally suited to provide optimal performance in different situations. Therefore, you’ll need to evaluate your specific screening application when choosing between horizontal and incline screens.

Horizontal Screens

Horizontal screens use either a linear or elliptical vibrating motion to move materials down the length of the screening deck. Because these decks are flat, they are more efficient at separating materials that are of similar size to the screening mesh. Horizontal screens are ideal for use:

- When portable screening or mobile screening is required

- When sorting sticky materials which may blind the openings

- When angular materials are passing through coarse openings

- When smooth, round materials are being screened (such as gravel)

- When maximum separation is required

Incline Screens

Incline screens use gravity to move material down an incline of approximately 20 degrees to the screening deck. Forces of gravity cause the material to increase in speed throughout the process, allowing higher volumes to be sorted. Incline screens are preferred when:

- Rinsing fine crushed materials

- Materials aren’t sticky

- Volume of material sorted is more important than the efficiency of the sorting process

- Thick, heavy rubber or urethane screen materials are used

Power Screening Can Help

As the leading dealer for mobile screening equipment in the Rocky Mountain region, Power Screening can guide you through the process of choosing the right screening plant. We have a wide range of new and used screening equipment to choose from. We offer only the most durable, high quality equipment.

Contact us today to receive customized recommendations regarding the right screening plants for your application.

Aggregates are literally the foundation of our lives as Americans. They underlie everything: our homes, our roads, our schools, and our churches. Most things we encounter and use in modern life are made using aggregates, and after metals, aggregates are the second largest category of domestic nonfuel mineral production. The total value of processed aggregates for construction is $27 billion annually, with $17.8 billion worth of crushed stone. This is the largest single nonfuel mineral commodity and accounts for 22% of the total value of US nonfuel mineral production.

But what are aggregates, and how do we process them?

What Are Aggregates?

The Portland Cement Association (PCA) defines aggregates as “inert granular material such as sand, gravel, or crushed stone.” Sometimes they are referred to as “construction aggregates.”

Paradoxically, aggregates are created mostly by separating material. Using screens and filters, aggregates are separated into particles of different sizes to create selections of particles of roughly the same size and/or shape. Aggregates are often classified by the size of screen that they can fit through, with the classifications being grouped into “fine” and “coarse” classifications.

How Aggregate Processing Works

Aggregate processing can include many different steps depending on the specific material desired. However, all aggregate processing includes two steps: extraction and screening. Most aggregate processing also involves crushing.

Aggregate Extraction

The first step in aggregate processing is extraction. Aggregates must be extracted from their source. Usually this is a natural source such as a quarry. Stone, sand, and other materials are removed from the earth with heavy machinery such as excavators. However, sometimes aggregate extraction is performed at build sites, such as demolished roads and buildings, where broken concrete can be recycled into new aggregate.

Aggregate Crushing

Most of the time, aggregate emerges from extraction as masses larger than the final product desired. Aggregate crushing is the process of breaking down the large pieces into smaller particles, using several types of heavy machinery, including:

Aggregate Screening

Screening is the process of separating aggregates into their different size categories. Depending on the type of heavy machinery used, the source material, and the desired number and type of size categories, aggregate screening might be conducted in multiple stages.

Other Aggregate Processing Steps

In addition to the above, aggregate processing often involves other steps. Conveying, for example, is an automated process for transporting aggregate materials between the different steps. Washing might be necessary for some types of materials to help them meet the material standards. Calcination (exposure to high heat) might also be required to remove impurities.

Heavy Machinery for Aggregate Processing

All steps in aggregate processing require some type of heavy machinery. Here is a summary of some of the most common types of heavy machinery for aggregate processing.

Earthmoving

Earthmoving equipment like crawler or wheeled excavators, help extract aggregates from their source. Loaders, either crawler or wheeled, can transport the extracted materials from where they’re excavated to where they’re crushed and/or screened.

Conveyors

Conveyors are an efficient automated way to transport aggregate materials. Rather than have loaders move all the material, conveyors can transport a steady stream of materials to the place where they are crushed and/or screened. Conveyors can also help control the flow of materials so that it doesn’t overwhelm the crusher and/or screener.

Screens

Screens separate aggregate materials into their different size categories. Depending on the type of screen, they can separate the source material into multiple different categories at the same time.

Crushers

Aggregates often come out of the earth in much larger form than desired. Crushers break down the material into smaller pieces.

Wash Plants

Some types of aggregate must be washed to remove impurities and meet certain standards. Wash plants are heavy machinery that performs this task on the job site. Some are portable, while others are modular for assembly at the site and removal.

Do You Need Heavy Machinery for Aggregate Processing?

If you’re in Colorado, Utah, Wyoming, New Mexico, or Nebraska, and need heavy machinery for aggregate processing, let us help. Power Screening rents and sells heavy machinery for aggregate processing, demolition, and construction from three locations.

Request a quote with our online form or call us at (800) 231-5005 today to learn how we can help you.

You need a rock crusher for your next big job, but you don’t have one now. It’s time to get one, but should you buy or rent? Some people would have you think this is a simple math problem, but you know that when you’re running a company like yours, there’s a lot more than math involved, and the problems are never simple.

Here’s a quick guide to deciding which is the best choice.

Rock Crusher for Sale or Rent—Do the Math

Okay, so let’s get this out of the way. Here’s the simple math problem that people think answers the question: does it cost more to rent or to buy?

To calculate this answer, take the hourly cost of the rock crusher for rent and multiply it by the number of hours you expect to use the tool over its lifetime. Then compare that to the cost to buy the tool instead. Simple, right?

Not exactly. You have to consider both the cost of a new rock crusher for sale as well as a used rock crusher for sale. Considering the cost of the used rock crusher, you have to consider how much less time it might last. That’s always a tough question, especially for a piece of equipment that might get as much hard use as a jaw crusher for sale.

The number of hours you’re likely to use it isn’t easy to figure out, either. If this is your first real job that needs this equipment, you can’t be sure that you’ll get more, and then you end up getting stuck with an expensive piece of equipment you’re not using.

Read our article: How to Choose a Rock Crusher?

Do You Have a Good Storage Option?

A concrete crusher is not like a rotary hammer that you can hang up on your pegboard – you’ve got to have someplace to put your concrete crusher. If you aren’t sure you have a good place to put it, maybe now’s not the time to buy.

How Will You Transport It?

Just as you can’t hang a concrete crusher on your pegboard, you can’t just toss it in the back of your truck. You need to have a solution to transport it to your job site. Maybe you already have a tractor-trailer that can handle the rock crusher, but if not, you have to add transportation cost to the price of buying. On the other hand, if you rent the equipment, you can often get it delivered to the job site and picked up. That can save you a lot of time and hassle.

Can You Bill It?

One way to cut your costs whether you’re looking for a jaw crusher for sale or a concrete crusher for rent is to bill it to the job. This will depend on what you bid on the job, the terms of the contract, and other variables. Whether you can bill it to the job – and how much you can bill for – will make a big difference in the net cost of the tool to you.

How Much Can You Deduct?

Whether you buy or rent, you can likely deduct all or part of the cost of the tool. For a tool of this price, it’s worth talking to your accountant and figuring out how much of a difference it might make on your taxes to rent vs. buy the tool. Then you can add this into your cost calculations, because it could significantly cut the net cost of the tool.

Will It Help You Get More Work?

When you’re bidding for jobs, you might find that having a rock crusher could be a competitive advantage. You might be able to bid a lower cost, promise a better schedule, and offer to do more work depending on the features of the rock crusher. Plus, you’ll never have to worry about finding a rock crusher when you need one in the event that there aren’t many available for rent.

Can You Get Value Even If You’re Not Using It?

If you have a rock crusher that you’re not using, you might be able to loan it to other companies who need it. Potentially, you could even rent it out yourself and make back some of the purchase cost.

How Much Is Maintenance?

Don’t forget to factor maintenance into your cost calculations. A rock crusher takes a beating and can need a lot of regular work to keep it in top shape. When you get a concrete crusher for rent, the rental center handles the worst of the maintenance costs.

Get a Quote to Make a Decision

As you can see, there’s a lot of factors to consider when trying to answer this question. At Power Screening, we have both rock crushers for rent and for sale. This helps us stay neutral on the question and lets us talk to you about your options to find the one that is most practical and profitable for your operation.

Whatever decision you come to, however, you have to start by knowing the cost of the two options. To get those costs, please contact Power Screening for a free quote.

With aggregate processing, you depend on the machines to get the job done and choosing the best equipment for your job can make a big difference in your overall profitability. Here are a few important considerations to take into account when deciding on the aggregate equipment you want to rent or buy.

Considerations for All Aggregate Equipment

Before deciding on any aggregate equipment, you should consider these factors.

- Cost

- Quality

- Durability

- Maintenance

Of course, you need to factor in the cost of the equipment. All things being equal, you want to choose the less expensive aggregate equipment to support your profitability. However, all things are rarely equal, which is why you need to take some other factors into account.

You expect to pay more for more quality equipment. However, it’s important to not just assume that a piece of aggregate equipment is better because it costs more. Do your research and make sure you’re really getting what you pay for.

Aggregate equipment gets hard use. Rocks, sand, and dust all take their toll on the machines you use. And when the machines fail, it can cost you money and time. You want to make sure that the equipment you’re choosing is capable of standing up to the stresses you expect to put it under.

It’s important to factor in maintenance costs. Machines that are more expensive to buy are often more expensive to maintain, too, which can eat up the savings from not having the machine go down as often.

Don’t forget to factor in the time cost for maintenance. If a machine doesn’t have people around who can work on it, or a ready supply of spare parts, you might lose a lot of time from choosing an unusual aggregate machine.

Read our article: How to Choose a Rock Crusher?

Considerations for Aggregate Crushers

Crushing is one of the most important parts of aggregate processing, and crushers are expensive pieces of equipment. You want to make sure that the one you get is capable of doing the job you need it for. When you’re choosing a crusher, you need to take into account:

- Material hardness and uniformity

- Desired final product

- Mobility

Make sure the crusher you choose is capable of handling the material you want to process. It isn’t just hardness. Some crushers are better suited to dealing with homogeneous material – all one type – while others are better at mixed materials. Looking at the material you’re processing can help you decide between jaw crushers, cone crushers, and impact crushers.

You also have to factor in what type of product you’re trying to produce. Some crushers produce aggregate of certain shapes, while others produce them of different shapes. Some crushers produce more uniform particles, while others are less consistent.

Mobility can matter for your crusher, though it’s less important. If you expect your crusher to move around the site, you need to make sure it’s capable of doing it reasonably. However, if you plan on bringing all the material to your crusher, mobility doesn’t matter as much.

Considerations for Aggregate Screens and Conveyors

When choosing screens and conveyors, make sure to take into account:

- Initial/desired moisture

- Type of media

- Number and type of decks and outputs

Dealing with wet aggregate is very different than dealing with dry. If you’re going to be dealing with wet mixtures, make sure your equipment is capable of handling it. Also, make sure that your machine can help with drying and/or introducing the material to a dryer when necessary.

The type of media is also very important for your screens and conveyors. You need to be sure that the material won’t break your screens or overload your conveyors.

If you are going to be breaking your aggregate up into multiple categories, it’s important to make sure your screens are capable of handling this. Some screens have two, three, or more screen decks. Getting one that separates into the right number of categories can save you time and money at the worksite.

Let Power Screening Help You Find the Best Aggregate Equipment for You

At Power Screening, we are dedicated to helping all our customers find the best aggregate equipment for their application. We can talk through all these issues for you, and help you determine which is the one that will do best for the job you are working on. We can either rent or sell the equipment to you, and we’ll consult about how to make the choice about which is better for you.

With locations in Colorado, Utah and New Mexico, please contact Power Screening today and let our knowledgeable team assist you.

There’s a big job you want to bid, but to do it efficiently you’ll need a wheel loader. Or another wheel loader – it seems like you never have enough. Perhaps you even won the bid, and now you need to get the wheel loader to do the job. There’s just one question: is it better to buy or rent one?

This is a complicated question, but if you work it through, you can get the answer that works best for your business.

Wheel Loader for Sale or Rent: Start with the Math

There is a simple equation that should always be your starting point for making the decision to rent or buy a wheel loader: does it cost more to rent or buy?

To calculate this answer, take the hourly cost of renting a wheel loader and multiply it by the number of hours you expect to use the tool over its lifetime.

Estimating the number of hours you’ll use the tool is always challenging. For a versatile vehicle like a wheel loader, you’re likely to use it a lot. But maybe this is a compact wheel loader or a really large one that you will use less often.

Don’t forget to consider the cost of buying a used wheel loader. They might be much cheaper, but they might also not last as long, depending on how well they’ve been maintained.

Where Will You Store It?

When you buy a recip saw, you can just put it on the shelf or hang it on pegboard if you’re not using it. But a wheel loader – even a compact wheel loader – takes significant storage space. Maybe you’ve got a spot in your yard where it’d just fit or know a farmer who’ll let you park it in a fallow field. But if you don’t have a place to store it and would have to pay for parking when it’s not in use, factor that cost in.

How Will You Transport It?

Yeah, a wheel loader is faster than most of the equipment you use on a job, and sometimes you’ll drive it to the site, but if the loader is too large or the job is too far (or you don’t trust your drivers on the roads), you’ll need to have a transportation solution. If you’re renting, the rental company might provide a rental solution to make it easier.

Can You Bill the Wheel Loader?

One way to make your wheel loader cheaper is to bill some or all of the cost to the job. While you might be able to bill all the rental cost, even billing part of the purchase cost to the job might make buying cheaper.

If you’ve already won the job, make sure you review the terms of the contract and bid before trying to bill equipment to it. If you’re thinking about adding the cost to your upcoming bid, be aware that adding the cost of the wheel loader might make your bid less competitive. (However, if it’s the difference between having the job be profitable and making it a loss for you, it’s better to be less competitive.)

How Much Can You Deduct?

The cost of tools you get for a job can be deducted on your taxes whether you rent or buy. If you’ve done this before, you might have a sense of how much difference this makes, but if you’re not sure, talk to your accountant.

Will It Help You Get More Work?

Buying a wheel loader might be a better investment if it lets you bid and win more jobs. Maybe having another wheel loader is what’s been holding you back from running two teams simultaneously. Just make sure you have someone you can trust to promote to site manager before you invest too much into this strategy.

Can You Get Extra Value from It?

Some tools just sit in the yard when you’re not using it, but a wheel loader is a versatile, in-demand machine. You might be able to get extra value by renting it out when you don’t need it.

How Much Will You Pay in Maintenance?

When you rent a tool, the rental company takes care of all the wheel loader maintenance, but when you buy it all the costs are on you. Estimate how much this is likely to be, then factor that into the relative cost.

A Quote Can Help You Make the Decision

Before you can make your final decision, you need to know how much buying and renting a wheel loader will cost. Power Screening can supply you with a quote to help you make a decision on your wheel loader.

Please contact Power Screening today for a free quote and find out what we have available in Colorado, Utah, and New Mexico.

At Power Screening, we offer some of the highest-quality equipment available to our customers in all aspects of the waste and recycling process. Some great examples of this are the composting and shredding equipment we offer from Komptech. This equipment can be an indispensable addition to a recycling operation, improving efficiency, productivity, and profitability.

We wanted to take time to focus on some of these quality and efficient products to help you understand what sets them apart and how they can improve your recycling and/or composting operations.

About Komptech

Komptech is a leading international supplier of technology, machinery, and systems for the mechanical and mechanical-biological treatment of solid waste. Komptech equipment can even help turn waste biomass into a renewable energy source. With over 30 different types of machines that cover all steps of the modern waste handling process, the company’s focus is on innovative technology and solutions that provide the most benefit for your field operations.

Power Screening has maintained a strong and long-term relationship with Komptech Americas. We offer their high-quality mobile windrow turners and composting equipment as well as the genuine OEM parts necessary to keep them running properly. In addition, our trained team of technicians offer both shop and field support to keep your Komptech equipment up and running.

Compost Equipment: Windrow Turners

Windrow turners are great for open-air composting operations. The Komptech windrow turners efficiently stir large amounts of organic waste. This ensures the best processing for composting operations, turning waste into valuable product. Komptech machines provide power and reliability, combined with advanced technology and operator comfort. Most come in wheeled or tracked configurations so you can get the machine that’s best for your business.

We offer numerous types of Komptech compost equipment so you can find the best machine for your operation. The Komptech Topturn X4500 is a lot of composter in a little package. It provides the reliability and performance of the X-series in a small size that’s perfect for small- and medium-size operations. It’s a great entry-level turner.

The Komptech Topturn X5000 is a high performance compost windrow turner engineered to deliver optimally sized compost windrows, while being easily transportable and production-ready for most or operations. The Komptech Topturn X63 is an ox of a windrow turner. Capable of handling rows up to 6 meters in width (nearly 20 feet), it has a powerful engine and a well-designed drum to ensure smooth and fast operation in all conditions.

The Komptech Topturn X6000 is a modern engineered machine built to perform efficiently in the most demanding commercial composting applications with ease, comfort, and reliability. Shredding Equipment: Single-Shaft and Dual-Shaft Shredders

Shredding equipment is essential for recycling and waste operations. At Power Screening, we offer both Komptech single-shaft and dual-shaft shredders. These high-quality low-speed high-torque shredders utilize Caterpillar engines for power and efficiency.

Single-shaft shredders are optimal for shredding tires, mattresses, carpeting, municipal solid waste, and highly contaminated construction and demolition waste. Features like a remote-controlled hopper and a hydraulic drum drive capable of reversing at any time for self-cleaning make the Terminator shredders an excellent choice for appropriate applications. Depending on the material processed, the Terminator 3400 S can shred up to 55 tons per hour, while the 6000 S can double that.

Dual-shaft shredders are the best choice for stumps, green waste, food waste, construction and demolition debris with extensive wood, asphalt shingles, railroad ties, hay bales, pallets, and rigid plastics. Auto-reverse overload protection helps avoid damage and keeps the machines running smoothly. Low maintenance, operating, and fuel costs help the profitability of your waste operations. The Crambo 3400 can process up to 50 tons per hour, while the 6000 can process up to 110 tons per hour, depending on the type of material processed.

Let Power Screening Match You with the Best Waste & Recycling Equipment for Your Operation

If you are looking to add or upgrade machinery in your waste and recycling operation, Power Screening can help you find the best option for you. Since 1984, we have been serving customers in the West, and we understand the benefits and limitations of each machine so we can steer you to the ones that will work best for you.

From our locations in Henderson, CO, Albuquerque, NM, and Salt Lake City, UT, we serve clients in Colorado, New Mexico, Utah, Nebraska, Eastern Wyoming, and Southwest Kansas. Please call (800) 231-5005 or contact us online today to talk to an aggregate equipment expert at Power Screening.

Screening equipment plays a critical role in many construction projects, allowing you to more effectively filter materials of different sizes. As items such as rocks, minerals, composts and waste materials are fed into the machine, mesh screens of different sizes will be used to sort the material. Large objects will only fit through certain mesh screens, while smaller materials will continue being filtered through until they come into contact with a screen that won’t allow them to pass.

Two of the most common types of screening equipment are trommel screens and vibrating screens. Your specific applications and the materials being sorted will determine which of these machines is right for your needs. The discussion below will help you to better understand your options.

What Are Trommel Screens?

Trommel screens, also known as rotary screens, consist of a cylindrical drum that rotates on its axis. This drum is usually inclined at a certain angle to facilitate material separation. The cylindrical design enables effective screening of different-sized materials as they tumble through the drum.

Trommel screens utilize a rotational motion to lift and tumble materials, separating them based on size. The drum’s perforations allow smaller particles to pass through, while larger materials are conveyed to the end of the drum for further processing or collection.

These machines are frequently used in a variety of industries, including:

- Aggregates

- Waste management

- Composting

- Topsoil

In addition, their ability to efficiently separate materials of different sizes make them indispensable in scenarios where precise classification is crucial.

What Are Vibrating Screens?

Vibrating screens employ a rectangular or circular motion to convey materials along the screening surface. These screens consist of a vibrating mechanism that induces vibrations, promoting the movement of particles for effective separation.

Vibrating screens employ a rectangular or circular motion to convey materials along the screening surface. These screens consist of a vibrating mechanism that induces vibrations, promoting the movement of particles for effective separation.

Vibrating screens rely on their vibratory motion to convey materials along the screening surface. The amplitude and frequency of the vibrations can be adjusted to optimize the screening process. This dynamic motion is particularly effective in applications where a higher level of agitation is required.

These machines are very versatile and are commonly used in a wide range of industries, including:

- Construction

- Agriculture

- Aggregates

In addition, their ability to handle a wide range of materials and adapt to various screening requirements makes them a preferred choice in many scenarios.

Key Differences Between Trommel and Vibrating Screens

There are several important differences between trommel screens and vibrating screens which may determine which one is right for your specific application. When evaluating performance, you’ll see differences in efficiency and throughput capacity. You’ll also notice differences associated with maintenance and durability.

Differences in Efficiency

Trommel screens are known for their efficient screening of materials, especially in scenarios where precise classification is essential. Vibrating screens, with their dynamic motion, are adept at handling materials that require a higher level of agitation for effective separation.

Differences in Throughput Capacity

While both trommel and vibrating screens can handle large volumes of material, the choice depends on the specific throughput requirements of your application. Trommel screens are often favored for their high throughput capacity in certain scenarios where more screening work is required. Vibrating screens, on the other hand, are only able to filter a small amount of raw materials due to restrictions associated with the linear vibrating screen. As a result, they are often a better option for smaller jobs that involve filtering fine materials.

Differences in Ease of Maintenance

Trommel screens are generally easier to maintain, with simpler designs and fewer components. Vibrating screens may require more attention to ensure that the vibrating mechanisms are functioning optimally.

Differences in Durability

Both types of screens are designed to withstand the rigors of heavy-duty operations. Trommel screens, with their rotating drums, may have specific wear points, while vibrating screens may require attention to the vibrating mechanisms and screen surfaces.

Choosing the Right Screen for Your Needs

Understanding the unique requirements of your industry is crucial in making the right choice. For mining and aggregates, where precise classification is vital, trommel screens may be the ideal solution. In construction and demolition applications, where a higher level of agitation is often required, vibrating screens could prove more effective.

Understanding the unique requirements of your industry is crucial in making the right choice. For mining and aggregates, where precise classification is vital, trommel screens may be the ideal solution. In construction and demolition applications, where a higher level of agitation is often required, vibrating screens could prove more effective.

When making a purchasing decision, cost-effectiveness and customization options should also be taken into account. Trommel screens may offer cost advantages in certain scenarios, while vibrating screens provide versatility and adaptability to different materials and applications.

Power Screening Can Help

If you’re looking to purchase screening equipment, Power Screening can help. We’ve been the leading dealer for mobile aggregate screening equipment in the Rocky Mountain region since 1984. We have strong relationships with many of the leading manufacturers, enabling us to provide the highest quality screening equipment in the industry. Our vast selection of new and used equipment ensures we’ll be able to provide the right screening equipment to address your specific needs. In addition, we carry genuine OEM parts, and our technicians offer both shop and field support to ensure your equipment is running properly with as little downtime as possible.

Contact us today to learn more about our aggregate screening equipment solutions. Power Screening serves customers in Colorado, Utah, New Mexico, Nebraska, Eastern Wyoming and Southwest Kansas.

Material handling equipment is crucial for maintaining smooth operations in scrap yards. These machines provide a streamlined approach to handling scrap materials that minimizes downtime, optimizes workflow, and contributes to cost savings. Material handling equipment acts as the backbone of these operations, enabling your business to process materials quickly and effectively.

Types of Material Handling Equipment Used in Scrap Yards

Scrap yards rely on a variety of different types of material handling equipment to address the numerous tasks performed each day. Depending on your specific applications, your scrap yard may require a combination of the following machines:

- Excavators – Excavators are versatile machines with various attachments, making them ideal for tasks such as loading and unloading materials in scrap yards. Their ability to reach and maneuver in tight spaces enhances their utility.

- Grapples and Grabs – These specialized attachments are designed for securely gripping and lifting materials, making them essential for handling scrap metals and other materials efficiently. Grapples come in different configurations, including clamshell and orange peel designs, catering to various material types.

- Material Handlers – Specifically designed for material handling tasks, these machines are equipped with features like extended reach and powerful hydraulics. Material handlers excel at lifting and placing heavy loads, offering precision in scrap yard operations.

- Conveyor Systems – Conveyor systems facilitate the movement of materials within the scrap yard. They enhance efficiency by automating the transfer of materials from one location to another, reducing the need for manual labor and minimizing handling time.

Benefits of Using Specialized Material Handling Equipment in Your Scrap Yard

Material handling equipment delivers several critical benefits that optimize operations in scrap yards. These include:

Material handling equipment delivers several critical benefits that optimize operations in scrap yards. These include:

- Increased Efficiency and Speed – Specialized equipment is designed to handle materials quickly and efficiently, reducing processing times and increasing overall productivity in scrap yards.

- Enhanced Safety Features – Material handling equipment is equipped with safety features to protect operators from potential hazards. This ensures a secure working environment and reduces the risk of accidents.

- Reduction in Labor Costs – The automation provided by material handling equipment reduces the reliance on manual labor, leading to cost savings associated with lower labor expenses.

- Improved Environmental Sustainability – Optimized operations through material handling equipment result in reduced fuel consumption and emissions, contributing to a more environmentally sustainable approach.

Factors to Consider When Choosing Material Handling Equipment for Your Scrap Yard

It’s important to choose the right material handling equipment for your specific applications. The following considerations should help you determine the right solutions for your needs:

- Assess Your Specific Needs – Understanding the unique requirements of your scrap yard is essential for choosing the right material handling equipment. Factors such as the type and volume of materials processed influence the selection process.

- Evaluate Capacity and Capabilities – Matching the capacity and capabilities of the equipment to the demands of your scrap yard ensures optimal performance and prevents unnecessary wear and tear.

- Consider Maintenance and Total Cost of Ownership – Regular maintenance is key to extending the lifespan of material handling equipment. You should also consider the total cost of ownership, including maintenance and operational costs, when making purchasing decisions.

Tips for Maintaining and Extending the Lifespan of Material Handling Equipment

Implementing a routine maintenance schedule is crucial for keeping material handling equipment in optimal condition. This should include regular:

- Inspections to identify and address potential issues before they become serious

- Lubrication to ensure all parts continue working properly

- Part replacements, as needed, to prevent breakdowns and ensure continuous operation

In addition, it’s important to implement a thorough operator training schedule. Properly trained operators contribute to the longevity of your material handling equipment by ensuring it is used according to manufacturer guidelines. Make sure your training program covers safe and efficient operation practices.

Power Screening Can Help

If you’re looking to purchase material handling equipment for your scrap yard, Power Screening can help. We’ve been the leading dealer for material handling equipment in the Rocky Mountain region since 1984 and offer a robust selection of new and used equipment.

Power Screening is the authorized Liebherr dealer in Colorado and Norther New Mexico. Liebherr offers a wide range of material handling solutions that are custom engineered for these applications, and they have developed a reputation as being one of the industry leaders in material handling equipment.

Contact us today to learn more about our material handling equipment solutions. Power Screening serves customers in Colorado, Utah, New Mexico, Nebraska, Eastern Wyoming and Southwest Kansas.

Construction companies rely on efficient equipment to optimize their projects. Among these tools, the wash plant stands out as a crucial piece that plays a significant role in many construction project timelines. This equipment is responsible for ensuring the cleanliness of aggregates, and it directly impacts the quality and durability of structures. You have two primary options when purchasing new wash plants for your upcoming projects – portable wash plants and modular wash plants.

Choosing between a portable or modular wash plant can significantly influence project efficiency and flexibility. While portability offers mobility and adaptability to varying job sites, modular setups provide scalability and customization options for specific project requirements. Understanding the unique advantages and limitations of each type is essential for maximizing productivity and achieving optimal results in your projects.

What Are Wash Plants?

Wash plants are industrial-sized rock washers that use water and various degrees of pressure to clean earthy materials, such as gravel and stones. These materials are crucial components in the production of concrete, asphalt, and other construction materials, making the wash process a fundamental step in the supply chain.

The intricate mechanisms within wash plants dislodge buildup and contaminants found in mined materials. They employ a combination of vibrations and water jets to thoroughly cleanse the materials, ensuring that the end product meets stringent industry standards for cleanliness.

From heavy-duty pumps to high-pressure sprayers, the essential components of wash plants are designed to handle large volumes of material without compromising on precision and thoroughness. The water treatment and recovery systems are also critical, ensuring that environmental and regulatory standards are met while keeping operational costs in check.

Portable Wash Plants

Portable wash plants provide benefits associated with mobility and ease of transport. They can be moved from site to site, without extensive disassembly, offering on-the-go convenience.

Portable wash plants provide benefits associated with mobility and ease of transport. They can be moved from site to site, without extensive disassembly, offering on-the-go convenience.

For projects that span across multiple locations or geographically challenging sites, portable wash plants provide an option that can travel with your construction team and maintain the cleaning processes without disrupting the project timeline. This flexibility is particularly beneficial for companies with smaller, less predictable project scopes.

Portable wash plants can be ideal for small to medium-sized projects with shorter durations. They can also be the preferred choice for companies mixing supplies from several local sources, allowing them to maintain the cleanliness of their aggregates regardless of the material’s origin.

Modular Wash Plants

Modular wash plants are characterized by their fixed, yet versatile, design, where components can be easily assembled and disassembled. This modularity offers robust capabilities and adaptability to various project configurations.

Modular wash plants are known for their consistent performance over long operational periods. Their stationary setup enhances operational stability and mitigates the risks associated with frequent transport. For construction companies with expansive projects that require a high volume of cleaned aggregates, modular wash plants can offer continuous and dependable washing capability.

These wash plants can be custom designed to fit the specific requirements of large-scale projects. The modularity allows for the addition or removal of components, adapting to changes in the project scope. This tailored approach ensures that the wash plant operations are always aligned with the construction process.

Choosing Between Portable and Modular Wash Plants

The decision between portable and modular wash plants hinges on several factors, including:

The decision between portable and modular wash plants hinges on several factors, including:

- Project duration and location

- Operation and maintenance costs

- Environmental sustainability

- Budgeting and ROI considerations

Project Duration and Location

For long-term projects in fixed locations where space and logistics are not a concern, modular wash plants provide a comprehensive washing solution. Conversely, portable wash plants are optimal for shorter projects and those where the location may change. They are also a good fit for temporary needs or unexpected changes in project demands.

Operation and Maintenance Costs

Understanding and comparing the long-term costs associated with both types of wash plants is essential. Portable wash plants, due to their mobile nature, may require higher maintenance and set-up costs. On the other hand, modular wash plants benefit from fewer moving parts, leading to potentially lower maintenance costs over time.

Environmental Sustainability

In the wake of increasing environmental considerations, wash plants must integrate sustainable practices. This includes water recycling systems and quality control measures to ensure that waste materials are safely disposed of and that the washing process has minimal ecological impact. Modular wash plants, with their ability to house advanced water treatment systems, typically score higher on sustainable operations.

Budgeting and ROI Considerations

Companies looking for rapid setup and immediate return on investment may find portable wash plants more desirable. Their ease of transportation and affordability might help you experience a good ROI more quickly. However, modular wash plants offer long-term economic benefits through operational stability and potential cost savings in maintenance and servicing.

Power Screening Can Help

Ultimately, the right decision for you will depend on your specific applications for this equipment. At Power Screening, we can help you navigate this important decision and ensure you choose the right wash plant for your needs.

Power Screening has been the leading dealer for wash plant equipment in the Rocky Mountain region since 1984. We offer a robust selection of new and used equipment, including equipment from the leading manufacturers of wash plants. In addition, we carry genuine OEM parts, and our technicians offer both shop and field support to ensure your equipment continues to run properly with as little downtime as possible.

Contact us today to learn more about our new and used wash plant equipment. Power Screening serves customers in Colorado, Utah, New Mexico, Nebraska, Idaho, Wyoming and Southwest Kansas.