Get A Quote

To request a quote, please fill out the form below. A representative will respond to you as quickly as possible. Thank you.

IMPACT CRUSHERS FOR SALE AND RENT

- Home

- >

- Rock Crushers for Sale and Rent

- >

- IMPACT CRUSHERS FOR SALE AND RENT

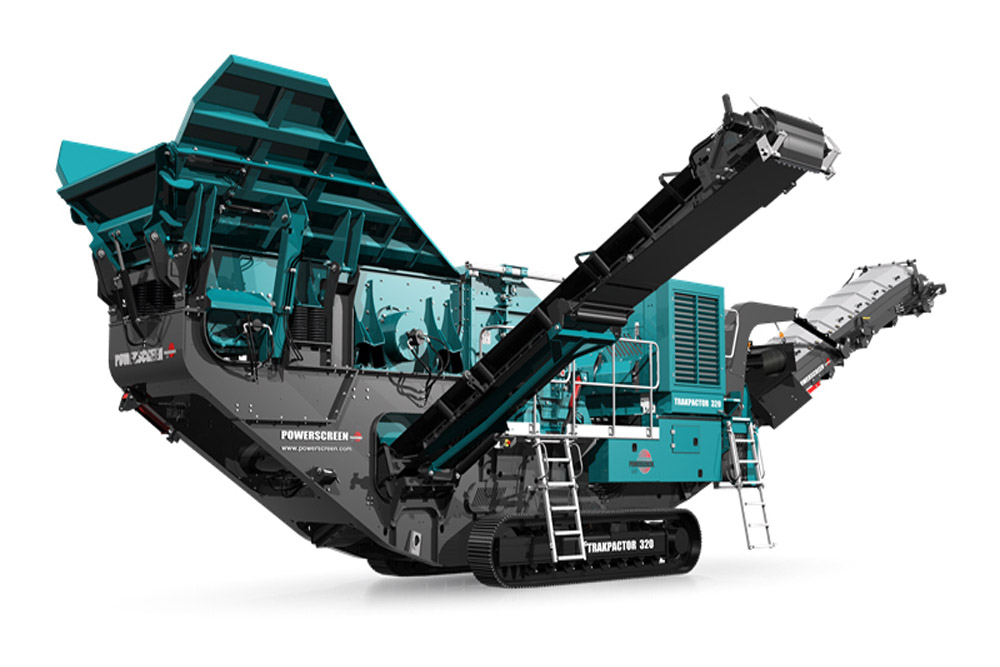

POWERSCREEN TRAKPACTOR 320

GLADIATOR TP320SR

GLADIATOR TP320SR

Weight: 94,006 lbs

Weight: 94,006 lbsOutput Potential: Up to 353 US tph (320tph)

Working Width: 18' 1"

Working Length: 68' 10"

Working Height: 16' 6"

POWERSCREEN TRAKPACTOR 320SR

POWERSCREEN TRAKPACTOR 500

POWERSCREEN TRAKPACTOR 500

Weight: 115,919 lbs

Weight: 115,919 lbsOutput Potential: Up to 550 tons/hr

Working Width: 23' with side conveyor deployed

Working Length: 56'

Working Height: 13' 6"

Impact Crushers

Power Screening is your leading source for impact crusher sales, rental, parts and service in the Rocky Mountain region. With branches in Henderson, Colorado, Albuquerque, New Mexico, and Salt Lake City, Utah, the team of professionals at Power Screening are ready to assist with your impact crusher questions and needs.

The impact crusher range from Power Screening is ideal for shaping applications including making chips, sand, concrete manufacture, and glass recycling. The range includes both horizontal and vertical impact crushers. They can be used for a wide range of applications, including:

- Construction and demolition (C&D) waste

- Foundry waste

- River rock

- Blasted rock

- Processed minerals

- Processed ores

Powerful rotors and durable impact bars allow a high reduction ratio and excellent reliability.

See all rock crushers for sale.

How an Impact Crusher Works

Understanding how an impact crusher works will help you appreciate the benefits of Powerscreen impact crusher options. If you already have a firm grasp of how an impact crusher works, skip to the options for impact crushers for sale or rent.

In a horizontal impact crusher, materials fed into the impact chamber are struck by a blow bar attached to a rotor. The blow causes the materials to split along weak points and lines of fracture. The broken pieces bounce around in the impact chamber until they are small enough to pass between the rotor and the breaker plate. Adjusting the breaker plate controls the size of output aggregate, described as the closed side setting (CSS).

In a vertical impact crusher, materials feed through a central shaft where an impeller strikes them and propels them into the crushing cavity at a high speed. The material then strikes breaker plates and falls out through a discharge hopper.

Options for Impact Crushers for Sale or Rent

Blow Bars: Three material choices for blow bars: chrome, martensitic, and martensitic-ceramic. Chrome bars provide maximum abrasion resistance, but must have limited material feed size. Martensitic blow bars are good all-purpose blow bars with high impact resistance, but lower abrasion resistance. Martensitic-ceramic blow bars offer a compromise with higher abrasion resistance over straight martensitic blow bars.

Hammers: Choose 4 full size or two full and 2 half-size hammers.

Tine Bar Apertures: Choose from a wide variety.

Grizzly Cartridges or Blanking Mats

Side Conveyor for more versatile operation.

Magnet Separators to catch metal in output.

Belt Scale to precisely measure productivity in real time.

Plant Lighting to extend the workday or operate during off-hours.

Radio Remote Control to remotely start, stop, or adjust operation.

Hot/Cold Climate Oil Kits for optimal operation year-round at all job sites.

Blow Bar Removal Tool to speed replacement of damaged or worn blow bars and allow rapid changeout to customize blow bar to specific jobs.

Control Panel Positive Pressurization to protect control panel from dust infiltration.

Fully Independent Under Crusher Vibrating Pan Feeder for more efficient feeding of output.

Hopper Extensions to allow larger loads and fewer spills for more efficient continuous operation.

Refueling and Water Pumps for more efficient and longer continuous operation.

Pre-Screening to control quality of input.

Note: These options are all offered by Power Screening, but option availability for impact crushers for sale and impact crushers for rent may differ for specific models and at specific locations and times. Contact Power Screening to inquire about option availability and pricing.

Read our article: How to Choose a Rock Crusher?

Powerscreen Trakpactor 260 & 260SR

The Powerscreen Trakpactor 260 and 260SR are mobile impact crushers designed for the recycling and demolition markets. Capable of processing a wide range of material at a high output, these plants are versatile, easy to operate, and fuel efficient due to their direct drive system.

Both plants offer users excellent reduction and a high consistency of product shape alongside key features such as hydraulic overload protection. They offer an output potential of up to 275 tons per hour (tph).

The Powerscreen Trakpactor 260SR features a post-screen system and recirculating conveyor that can pass oversize material back to the crusher for further sizing or distribution as an additional product. A quick-detach single deck post-screen system allows the machine to convert to a standard Trakpactor 260 in minutes.

Powerscreen Trakpactor 320 & 320SR

The Powerscreen Trakpactor 320 is a mid-sized horizontal impact crusher designed to offer operators and contractors both excellent reduction and high consistency of product shape for performance in quarry and recycling applications. With track mobility, the plant is capable of working in the most demanding environments and features a rapid set-up time, fuel efficient direct drive system and excellent throughput capacity. They offer an output potential of up to 352 tph.

The Powerscreen Trakpactor 320SR features a screen and recirculating (SR) conveyor which returns oversized product to the crusher for further reduction, though it can be configured as an additional product output. It can quickly convert to a standard Trakpactor 320 when recirculation is not necessary.

Powerscreen Trakpactor 550 & 550 SR

The Powerscreen Trakpactor 550 is a horizontal shaft impactor which is versatile, efficient and highly productive. It offers both excellent reduction and a high consistency of product yield in quarrying, recycling, and demolition applications. The machine has been designed with excellent material flow and serviceability in mind. In addition, the machine can be configured for work safely and in record time as set-up is all carried out at ground level.

The robust Terex impact chamber features c-shaped blowbars as standard for better impact and a time-saving hydraulic adjust option.

The Trakpactor 550 has an output potential of up to 550 tph.

The Powerscreen Trakpactor 550SR features an SR section that allows for recirculation of materials for greater reduction or separation into additional product output. This section is designed for easy removal, letting the SR convert to a standard Trakpactor 550 in minutes.

Contact us today for more information on our wide range of Powerscreen impact crushers.

Weight: 77,779 lbs

Weight: 77,779 lbs Weight: 101,941 lbs

Weight: 101,941 lbs