Screening equipment plays a critical role in many construction projects, allowing you to more effectively filter materials of different sizes. As items such as rocks, minerals, composts and waste materials are fed into the machine, mesh screens of different sizes will be used to sort the material. Large objects will only fit through certain mesh screens, while smaller materials will continue being filtered through until they come into contact with a screen that won’t allow them to pass.

Two of the most common types of screening equipment are trommel screens and vibrating screens. Your specific applications and the materials being sorted will determine which of these machines is right for your needs. The discussion below will help you to better understand your options.

What Are Trommel Screens?

Trommel screens, also known as rotary screens, consist of a cylindrical drum that rotates on its axis. This drum is usually inclined at a certain angle to facilitate material separation. The cylindrical design enables effective screening of different-sized materials as they tumble through the drum.

Trommel screens utilize a rotational motion to lift and tumble materials, separating them based on size. The drum’s perforations allow smaller particles to pass through, while larger materials are conveyed to the end of the drum for further processing or collection.

These machines are frequently used in a variety of industries, including:

- Aggregates

- Waste management

- Composting

- Topsoil

In addition, their ability to efficiently separate materials of different sizes make them indispensable in scenarios where precise classification is crucial.

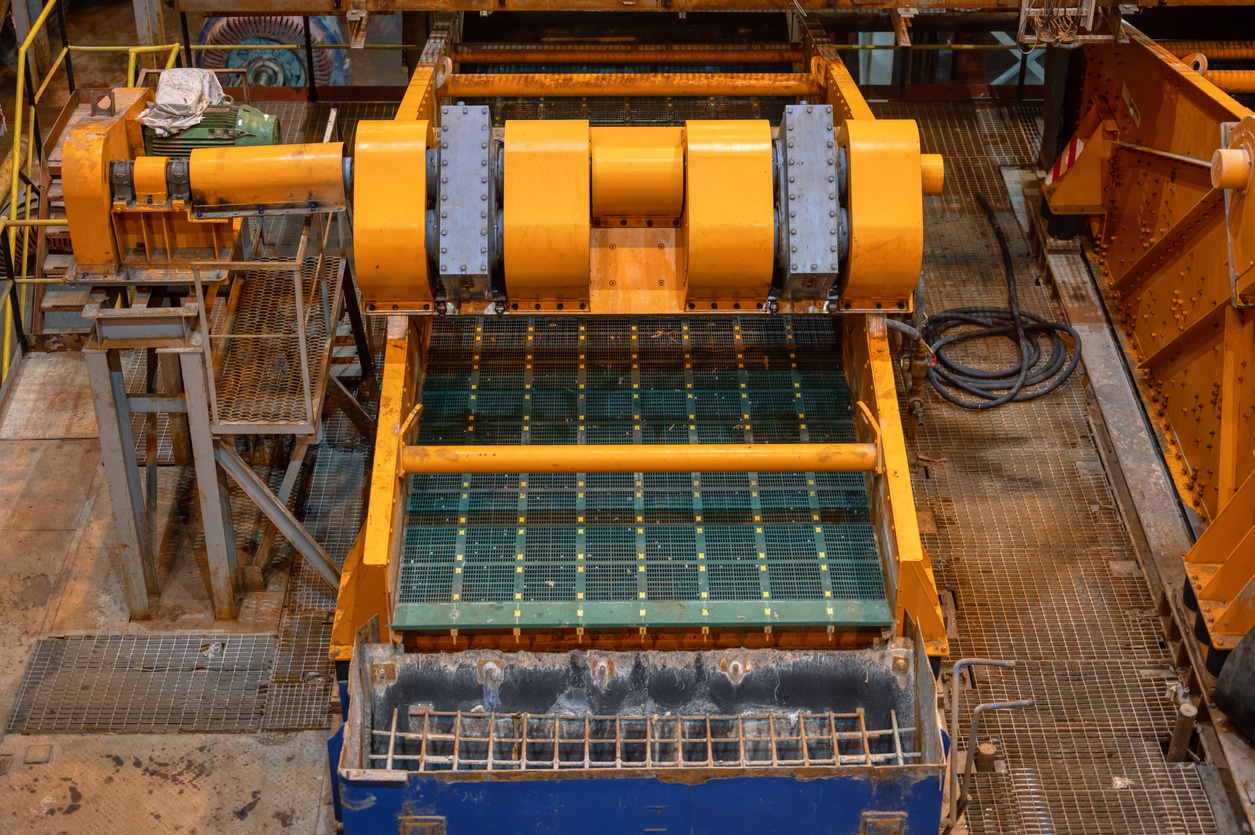

What Are Vibrating Screens?

Vibrating screens employ a rectangular or circular motion to convey materials along the screening surface. These screens consist of a vibrating mechanism that induces vibrations, promoting the movement of particles for effective separation.

Vibrating screens employ a rectangular or circular motion to convey materials along the screening surface. These screens consist of a vibrating mechanism that induces vibrations, promoting the movement of particles for effective separation.

Vibrating screens rely on their vibratory motion to convey materials along the screening surface. The amplitude and frequency of the vibrations can be adjusted to optimize the screening process. This dynamic motion is particularly effective in applications where a higher level of agitation is required.

These machines are very versatile and are commonly used in a wide range of industries, including:

- Construction

- Agriculture

- Aggregates

In addition, their ability to handle a wide range of materials and adapt to various screening requirements makes them a preferred choice in many scenarios.

Key Differences Between Trommel and Vibrating Screens

There are several important differences between trommel screens and vibrating screens which may determine which one is right for your specific application. When evaluating performance, you’ll see differences in efficiency and throughput capacity. You’ll also notice differences associated with maintenance and durability.

Differences in Efficiency

Trommel screens are known for their efficient screening of materials, especially in scenarios where precise classification is essential. Vibrating screens, with their dynamic motion, are adept at handling materials that require a higher level of agitation for effective separation.

Differences in Throughput Capacity

While both trommel and vibrating screens can handle large volumes of material, the choice depends on the specific throughput requirements of your application. Trommel screens are often favored for their high throughput capacity in certain scenarios where more screening work is required. Vibrating screens, on the other hand, are only able to filter a small amount of raw materials due to restrictions associated with the linear vibrating screen. As a result, they are often a better option for smaller jobs that involve filtering fine materials.

Differences in Ease of Maintenance

Trommel screens are generally easier to maintain, with simpler designs and fewer components. Vibrating screens may require more attention to ensure that the vibrating mechanisms are functioning optimally.

Differences in Durability

Both types of screens are designed to withstand the rigors of heavy-duty operations. Trommel screens, with their rotating drums, may have specific wear points, while vibrating screens may require attention to the vibrating mechanisms and screen surfaces.

Choosing the Right Screen for Your Needs

Understanding the unique requirements of your industry is crucial in making the right choice. For mining and aggregates, where precise classification is vital, trommel screens may be the ideal solution. In construction and demolition applications, where a higher level of agitation is often required, vibrating screens could prove more effective.

Understanding the unique requirements of your industry is crucial in making the right choice. For mining and aggregates, where precise classification is vital, trommel screens may be the ideal solution. In construction and demolition applications, where a higher level of agitation is often required, vibrating screens could prove more effective.

When making a purchasing decision, cost-effectiveness and customization options should also be taken into account. Trommel screens may offer cost advantages in certain scenarios, while vibrating screens provide versatility and adaptability to different materials and applications.

Power Screening Can Help

If you’re looking to purchase screening equipment, Power Screening can help. We’ve been the leading dealer for mobile aggregate screening equipment in the Rocky Mountain region since 1984. We have strong relationships with many of the leading manufacturers, enabling us to provide the highest quality screening equipment in the industry. Our vast selection of new and used equipment ensures we’ll be able to provide the right screening equipment to address your specific needs. In addition, we carry genuine OEM parts, and our technicians offer both shop and field support to ensure your equipment is running properly with as little downtime as possible.

Contact us today to learn more about our aggregate screening equipment solutions. Power Screening serves customers in Colorado, Utah, New Mexico, Nebraska, Eastern Wyoming and Southwest Kansas.