Get A Quote

To request a quote, please fill out the form below. A representative will respond to you as quickly as possible. Thank you.

JAW CRUSHERS FOR SALE & RENT

- Home

- >

- Rock Crushers for Sale and Rent

- >

- JAW CRUSHERS FOR SALE & RENT

POWERSCREEN METROTRAK HA

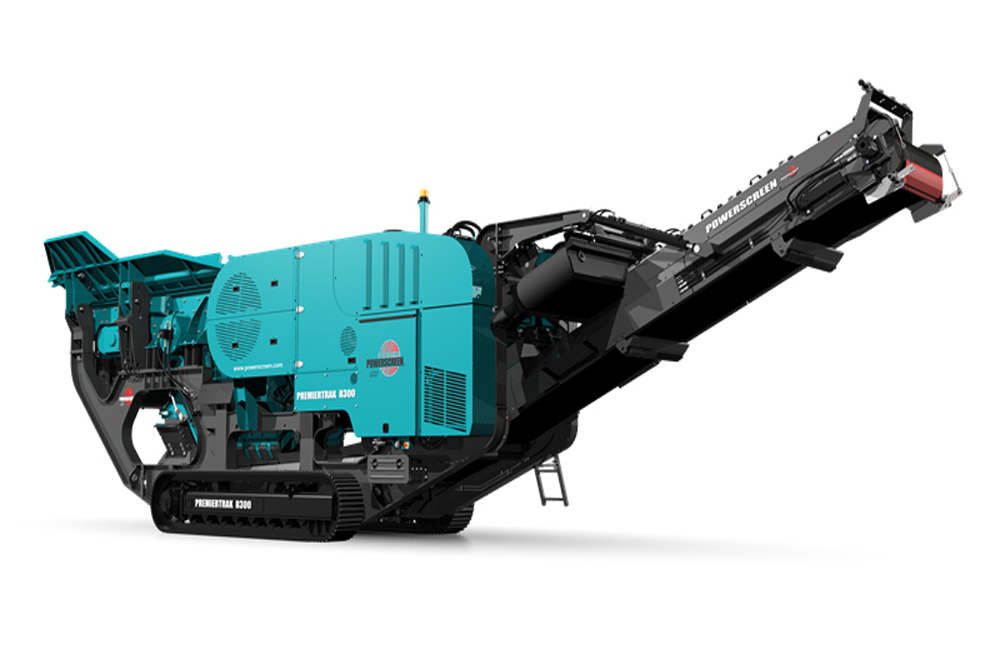

POWERSCREEN PREMIERTRAK 300

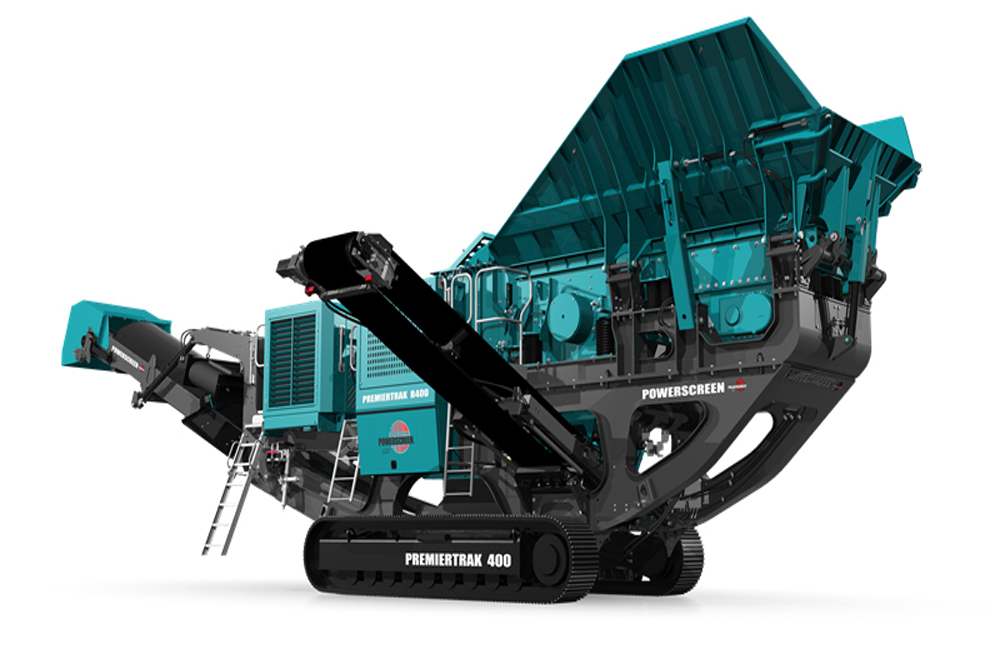

POWERSCREEN PREMIERTRAK 400

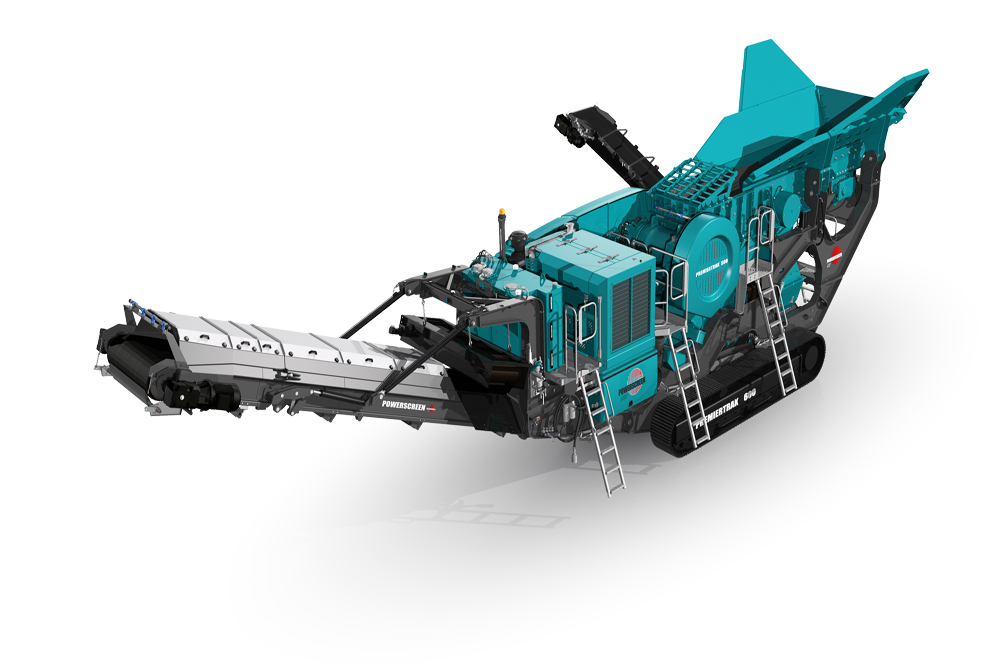

POWERSCREEN PREMIERTRAK 600

GLADIATOR PT450

GLADIATOR PT450

Weight: 96,200 lbs

Weight: 96,200 lbsOutput Potential: 420 US tph / 400 tph

Working Width: 11' 2"

Working Length: 52' 9"

Working Height: 13' 6"

GLADIATOR PT600

GLADIATOR PT600

Weight: 113,027 lbs

Weight: 113,027 lbsOutput Potential: 661 US tph / 600 tph

Working Width: 11' 10"

Working Length: 55' 1"

Working Height: 16' 1"

Powerscreen Jaw Crushers for Sale and Rent

Power Screening is your leading source for jaw crusher sales, rental, parts and service in the Rocky Mountain region. With branches in Henderson, Colorado, Albuquerque, New Mexico, and Salt Lake City, Utah, the team of professionals at Power Screening are ready to assist with your jaw crusher questions and needs.

Powerscreen jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications.

See all Power Screening Rock Crushers for Sale and Rent

How a Jaw Crusher Works

Understanding how a jaw crusher works is important for appreciating some of the options available in our jaw crushers for sale or rent. If you are familiar with the standard workings of a jaw crusher, you can skip directly to the options.

Jaw crushers work by crushing rocks between two jaws:

- Fixed jaw

- Movable jaw (also called the swing jaw)

The fixed jaw and the movable jaw are angled from one another, creating a triangular space between them, which is wider at the top (the gape width) where material enters than at the bottom, where product leaves. The angle between the two jaws is known as the nip angle. The nip angle should be chosen to ensure proper crushing of the material. Too large of an angle can cause boiling, where material slips up and down in the chamber without getting crushed.

The movable jaw, driven by an eccentric shaft attached to a gear or flywheel, opens and closes, moving a distance known as the stroke. The stroke is the distance between the crusher’s open side setting and the closed side setting. The open side setting is the largest particle size the crusher will let out. When the jaw opens, it lets material fall down between the jaws. When it closes, the jaws grip the material and crush it. Then the jaws open and material falls down further in the chamber to get caught and crushed again.

The most common jaw crusher designs are single toggle and double toggle. In a single toggle jaw crusher, the jaw is connected directly to a flywheel that governs its open-and-close motions. In a double toggle, the eccentric shaft attaches to a pair of toggles that then help to drive the jaw motion.

Read our article: How to Choose a Rock Crusher?

Options on Jaw Crushers for Sale or Rent

Powerscreen jaw crushers can work in diverse industries and under a wide range of conditions. Choosing the best options for your jaw crusher can help you operate more efficiently and profitably. It can also help you take on a wider range of jobs so you can stay profitable and increase the return on investment from your jaw crusher.

Hydraulic Deflector Plate: This adjustable deflector plate helps protect the conveyor from damage and is especially useful in recycling operations.

Side Conveyor: Lets you output a second product or feed output back to the chamber for further crushing.

Single Pole/Twin Pole Magnet: Separate metals from material to be crushed to avoid damage to jaws or teeth.

Radio Remote Control: Start, stop, or adjust your jaw crusher from anywhere on the job site.

Belt Weigher: Monitor the production of your jaw crusher in real time.

Refueling and Water Pumps: For more efficient long-term operation: save time and money.

Extended Hopper: Feed more material into the crusher to keep production running smoothly.

Jaw Profiles: The right jaw configuration can speed processing and extend jaw life. All jaw profiles are 18% manganese, proven effective in quarry and recycling operations. In addition to the standard super tooth jaws, choose from quarry tooth jaws, pyramid tooth jaws, and even heavy-duty jaws for the fixed jaw.

Hot and Cold Climate Configuration: Keep working in hot and cold weather.

Control Panel Positive Pressurization: Keep dust out of the control panel.

Powerscreen Pulse: Use a cell phone or satellite network to relay performance and production data for monitoring via the web.

Note: These are all options offered by Powerscreen, but option availability for jaw crushers for sale and jaw crushers for rent may differ at specific times and at specific locations. Contact Power Screening to inquire about option availability and pricing.

Jaw Crushers for Sale or Rent

Powerscreen Metrotrak Jaw Crusher

The new Powerscreen Metrotrak compact tracked mobile jaw crushing plant utilizes the “M” series single toggle to achieve an aggressive crushing action and a high output even at tight settings, up to 220 US tons per hour (tph). The Metrotrak is ideally suited for operators working in urban locations or where space is restricted. It performs well in diverse industries, including mining, quarrying, and recycling.

The new Metrotrak builds on the previously successful model with upgraded features, additional options, and slick new styling. With a hydraulically adjusted, fuel efficient direct drive chamber as standard, users benefit from an ability to quickly and easily change the size of finished product with minimal running costs.

Powerscreen Premiertrak 300 Mobile Jaw Crusher

The Powerscreen Premiertrak 300 high performance, mobile jaw crusher range has been designed for medium scale operators in quarrying, demolition, recycling & mining applications. The range includes the Premiertrak 300 with hydraulic adjust and the Premiertrak R300 with hydraulic release. User benefits include track mobility for a quick set-up time, hydraulic crusher setting adjustment for total control of product size and crusher overload protection to prevent damage by un-crushable objects. Output up to 308 US tph.

Powerscreen Premiertrak 400X Portable Jaw Crusher

The Powerscreen Premiertrak 400X range of portable jaw crushers use an aggressive jaw action to achieve high productivity – up to 441 US tph. Track mobility helps with easy set-up – they can be up and running in under 30 minutes. Hydraulic crusher setting adjustment gives total control of product size, plus crusher overload protection helps avoid damage by uncrushable objects. They are perfect for medium scale operators in quarrying, demolition, recycling and mining applications.

Powerscreen Premiertrak 400X Post-screen

The Powerscreen Premiertrak 400X Post-screen, is a tracked jaw crusher which excels in quarrying, demolition, recycling, and mining applications. The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with hydraulic release. The Premiertrak 400X post-screen offers additional output separation, allowing users to generate a type one product at high volume from one machine. It has been designed so that it has a quick release system, to ensure maximum uptime and easy service and maintenance.

Powerscreen Premiertrak 600

The Powerscreen Premiertrak 600 and Premiertrak 600E are built for the toughest applications. Their rugged construction and modern design combine reliability, optimal performance, and efficiency. Both utilize the high performance 1200 mm x 820 mm Terex chamber.

The Premiertrak 600E adds the benefit of an onboard diesel generator. The generator not only powers the machine, but offers sufficient additional power to supply a second machine, such as a screener. The additional versatility and the efficiency of the electrically driven crusher and conveyors make the PT 600E highly economical and environmentally friendly.

With an output of up to 661 US tph, these jaw crushers are optimal for large and medium-scale operators in numerous industries, including quarrying, mining, demolition, and recycling.

Used Jaw Crushers for Sale

Visit our available used jaw crushers for sale. Please note, this link will take you off the current website to our used aggregate equipment for sale website.

Contact us today for more information on our wide range of Powerscreen jaw crushers.

Weight: 62,831 lbs

Weight: 62,831 lbs Weight: 81,041 lbs

Weight: 81,041 lbs Weight: 98,656 lbs

Weight: 98,656 lbs Weight: 162,535 lbs

Weight: 162,535 lbs