Get A Quote

To request a quote, please fill out the form below. A representative will respond to you as quickly as possible. Thank you.

CONE CRUSHERS

- Home

- >

- Rock Crushers for Sale and Rent

- >

- CONE CRUSHERS

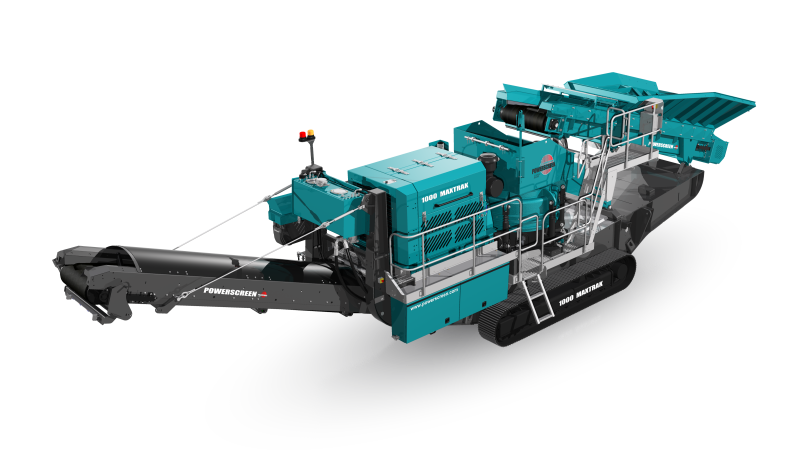

POWERSCREEN 1000 MAXTRAK

POWERSCREEN 1000SR

POWERSCREEN 1150 MAXTRAK

POWERSCREEN 1300 MAXTRAK

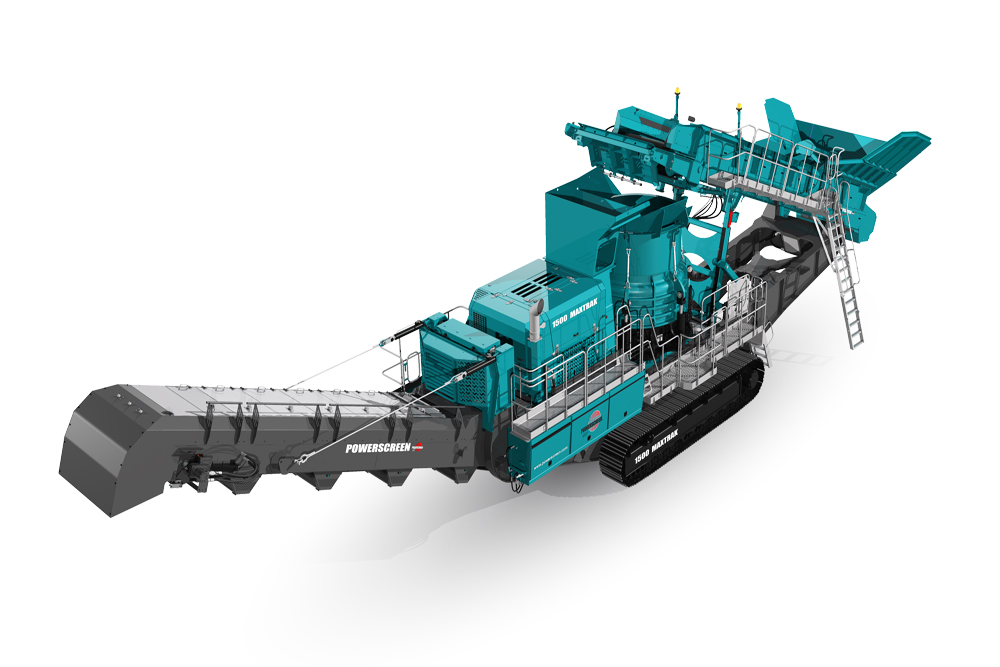

POWERSCREEN 1500 MAXTRAK

Powerscreen Cone Crushers for Sale and Rent

Power Screening is your leading source for cone crusher sales, rental, parts and service in the Rocky Mountain region. With branches in Henderson, Colorado, Albuquerque, New Mexico, and Salt Lake City, Utah, the team of professionals at Power Screening are ready to assist with your cone crusher questions and needs.

The Powerscreen range of mobile cone crushers are suitable for secondary and tertiary crushing in direct feed applications. They can be used for:

- Sand and gravel

- Blasted rock

- River rock

- Construction and demolition (C&D) waste

- Foundry waste

- Processed ores

- Processed minerals

The range uses advanced Automax® crusher technology to provide high volumes of excellently shaped product.

See all Power Screening rock crushers for sale.

How a Cone Crusher Works

Having a firm grasp of how a cone crusher works will help you understand the benefits of Powerscreen cone crusher options. If you already understand how a cone crusher works, skip to the options for cone crushers for sale or rent.

A cone crusher crushes rock between the cone-shaped mantle and the exterior of the chamber or bowl, also called the concave. The crushing motion is provided by an eccentric gear that causes the cone to wobble, creating wider (open) spaces on one side of the cone to let material enter and fall through the chamber. On the opposite side of the cone, there are narrower (closed) spaces where most of the active crushing occurs.

At the bottom of the cone, crushed material is allowed to pass through. The largest size aggregate that passes through the cone crusher is determined by the open side setting (OSS). The smallest size the aggregate cone crusher will crush to is determined by the closed side setting (CSS). Smaller sized particles can be produced in the aggregate cone crusher secondary to large particle crushing and small particles from your feed will pass through with little to no crushing.

The difference between the OSS and the CSS is determined by the “throw” of the eccentric gear. Long-throw or high eccentric gears have fewer crushing zones and produce a less uniform aggregate particle size. Short-throw or low-eccentric gears have more crushing zones and produce a more uniform aggregate particle size. However, long-throw eccentric gears process aggregate at a much higher speed.

Options for Cone Crushers for Sale or Rent

Powerscreen gives you options to customize your cone crusher for each job so that you can get the processing speed and particle size you desire for your final product, while accommodating the input feeds you must deal with on this job.

Gear Eccentricity: Choose long-throw or short-throw eccentricity to control aggregate particle uniformity and processing speed.

Concaves: There are five different options for concave and mantle liner profiles: Autosand®, medium coarse, coarse, extra coarse, and heavy duty. This lets you select the liners that accommodate the feed you are using and produce the desired output aggregates. These also affect processing speed and machine wear to help you maximize productivity and profitability.

Feed Hopper Extension Plates: Load more feed into your hopper at one time to maintain continuous processing.

Product Conveyer Belt Weigher: Lets you monitor productivity in real time.

Pumps: Refueling, water, and urea pumps make maintenance easier and help the cone crusher keep operating with little downtime.

Radio Remote Control: Remotely start, stop, or adjust operation.

Note: these are all options offered by Powerscreen, but option availability for cone crushers for sale and cone crushers for rent may differ at specific locations and at specific times. Contact Power Screening to inquire about option availability and pricing.

Automax® Cone Crusher

At the heart of every Powerscreen cone crusher is the Automax® cone crusher with hydraulic setting, tramp release & unblocking system. Its unique crushing action provides excellent capacity, high reduction and good product cubicity for the production of high quality aggregate and sub-base materials.

The powertrain is designed to deliver maximum power to the cone, while minimizing friction loss. High-quality materials and the elimination of unnecessary components with efficient design helps eliminate “bowl bounce” and simplifies maintenance.

Powerscreen 1000 Maxtrak

The high performance Powerscreen 1000 Maxtrak portable rock crusher has been designed for direct feed applications without pre-screening on clean rock. It has an output potential of up to 253 tons per hour (tph).

Powerscreen 1000SR

The Powerscreen 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model. A re-circulating conveyor lets the 1000SR operate as a two-stage cone crusher. A double-deck post-screen helps provide a complete crushing and screening process on a single chassis. No pre-screening is required on clean rock for this direct-feed machine. In secondary and tertiary applications, the 1000SR can produce two different products with re-circulation or up to three products when oversized material doesn’t require re-circulation to the crusher. It has an output potential of up to 253 tph.

Powerscreen 1150 Maxtrak

The high performance Powerscreen 1150 Maxtrak is a medium sized tracked cone crusher which has been designed for direct feed applications without pre-screening on clean rock. It has an output potential of up to 330 tph.

Powerscreen 1150 Maxtrak Pre-Screen

The Powerscreen 1150 Maxtrak Pre-Screen is a high performance, medium sized track mobile rock crusher with an independent pre-screening system. The added pre-screen option maximizes output capacity and quality by removing dirt and/or a sized product before feed enters the cone. It has an output potential of 330 tph of highly uniform aggregate.

The patent pending hydraulic folding system lets the Powerscreen 1150 Maxtrak prescreen to convert rapidly between pre-screen and direct feed configurations. This provides unrivalled versatility and productivity. A level probe over the feed ring regulates the feed belt to ensure choke feeding of the cone chamber, essential for maximum reduction, manganese life, and optimal product shape.

Powerscreen 1300 Maxtrak

The Powerscreen 1300 Maxtrak is a portable cone crushing plant which is ideally suited to secondary applications such as taking an all-in feed from a primary crusher. Based around the 1300 Automax® cone crusher, the plant excels in the production of sub-base or aggregates, providing excellent cubicity, throughput and reduction ratios. It has an output potential of up to 386 tph.

Powerscreen 1500 Maxtrak

The Powerscreen 1500 Maxtrak cone crusher is one of the largest mobile cone crushers available on the market. Specifically developed for users requiring higher tonnage, the plant can accept an all-in feed from a primary crusher to produce large volumes of aggregate, up to 1047 tph.

With the Powerscreen 1500 Automax® cone crusher, operators benefit from hydraulic overload protection, a large throughput, excellent product cubicity, and a high reduction ratio.

Contact us today for more information on our wide range of Powerscreen cone crushers.

Weight: 67,108 lbs

Weight: 67,108 lbs Weight: 87,391 lbs

Weight: 87,391 lbs Weight: 94,578 lbs

Weight: 94,578 lbs Weight: 105,745 lbs

Weight: 105,745 lbs Weight: 196,211 lbs

Weight: 196,211 lbs